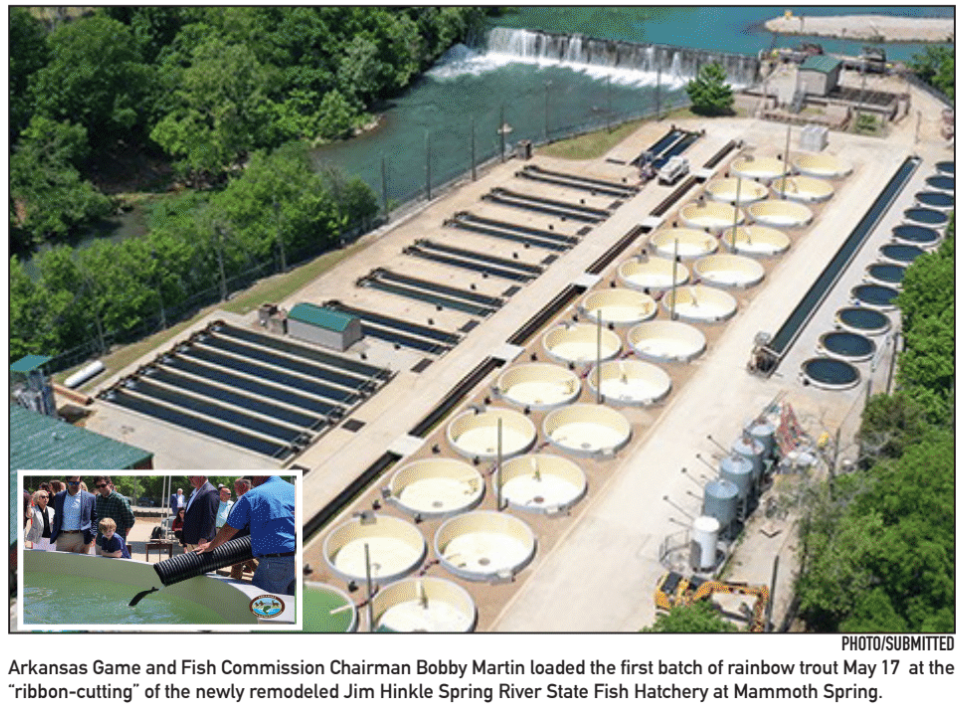

Arkansas Game and Fish Commission Chairman Bobby Martin loaded the first batch of rainbow trout May 17 at the “ribbon-cutting” of the newly remodeled Jim Hinkle Spring River State Fish Hatchery at Mammoth Spring. The hatchery, Arkansas’s only state-owned cold water hatchery, supplies rainbow trout to 43 locations throughout The Natural State, including the famed White, Norfork and Spring rivers. The hatchery, which was originally built in 1974 and was donated to the AGFC by the Kroger Company in 1985, draws cold water from the Spring River, hatches eggs supplied through federal trout hatcheries and cares for the trout until they reach about12 inches. The process takes about 16 to 18months from egg to stocking-size fish. “At its peak the hatchery was able to supply more than 1million rainbow trout per year, but it’s been a long time since we have reached those production numbers, ”B.J. Vandiver, hatchery manager for the AGFC, said. Federal hatcheries supplied the remain-der of Arkansas’s trout each year, bringing the total trout stocked by federal and state sources above 2million fish in some years. Commission Chairman Bobby Martin and Director Austin Booth releasing trout-time had taken its toll on the hatchery’s infrastructure, causing managers to shutdown nearly half of the facility’s trout-pro-duction capacity.“ There were 36 met-al silos where we had grown trout that had been taken out of pro-duction well before the renovation. They were 13 feet deep and17 feet wide,” Vandiver said. “They were over 50 years old and had deteriorated to the point that the walls were only half as thick as they should have been. When you pulled water out of them, the walls were beginning to bulge and became a safety hazard for anyone who had to work in them to transfer trout to trucks.” The outdated metal structures were re-placed with 24 concrete silos that measure only 7 feet deep but accommodate the same amount of trout with their 28-foot diameter. The new design not only is safer, but it is also more efficient, with drains at the bottom of each silo to evacuate water.“ We had to pump all the water out of the old silos with every batch of fish to eliminate any biosecurity issues and there really wasn’t a way to drain it completely,” Van-diver said. “These are much easier to drain and clean. They also will be much easier to harvest fish from when they are ready. ”Martin gave his appreciation to the many people who came together to make the renovation possible at a small gathering of stakeholders at today’s event. He spoke of the trout anglers who came together to support a raise in Arkansas’s trout stamp, which was a key factor in completing the renovation.“ Aging infrastructure is a challenge, but when it comes to this hatchery, we’ve been so very fortunate to be able to work with the trout industry, with our legislature and with our fishing public to be able to increase the cost of trout permits and make this possible.” Martin said.“ Out of that, we were able to raise nearly$3.6 million of the$7.6 million we invested in this facility’s renovation. ”There are a few finishing touches left to complete, but Vandiver hopes to have the hatchery rolling out trout at production levels it hasn’t seen in more than a decade. The expanded space also should allow AGFC staff to try some new techniques to increase production or efficiency at the hatchery. Increased capacity will enable fish to be raised at lower densities, which may increase growth rates and cut down rotation time or enable the hatchery to pro-duce slightly larger fish before they are stocked. “We still need to look at some of those new options, but things are looking good and we’re very happy with the new setup,” Vandiver said